Manual or Robotized.

Development Expertise

Development expertise

SPPP teams are sized to undertake global projects from the management of our injection partner to part packaging definition. Our development process is rigorously mastered and complies with all automotives standards.

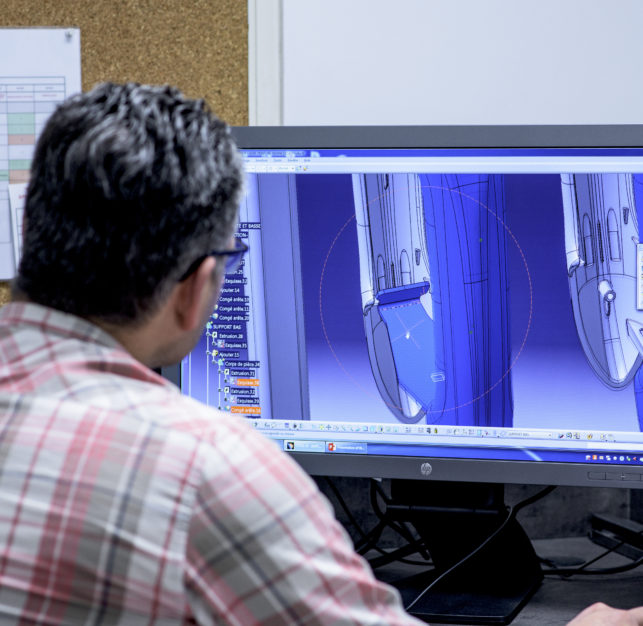

SPPP project teams are equipped with CATIA stations and able to exchange and interface with all customer’s datas. Additionaly, 3D printers complete the array of quick protyping solutions available at SPPP.

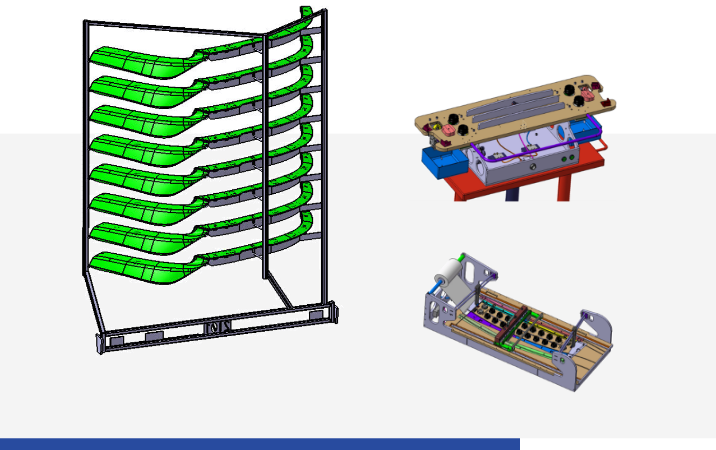

All production means necessary to support the painting operations are designed and partially produced in house. Jigs to hold raw parts, assemble means, customer designed station to apply protective film on painted parts or specific packaging are examples of means realized. Upon request, SPPP can develop in house the plastics masking parts used in special painting operations where some surfaces needed to be obliterated and clear out of paint.

SPPP large diversity of production means can cope with quality in mass volume production. The flexibility of the production means can also undertake prototypes or trials sample production in a short lead time.

SPPP Teams are sized to undertake global projects from injection management to packaging defintion.

SPPP is equiped to manage complete PPAP qualification either with its own internal means or subcontracting.

- Internationnal Teams

- CAO-DAO (CATIA)

- Prototyping means : 3D printing

- Small Series

- Laboratory

- Internationnal Teams

- CAO-DAO (CATIA)

- Prototyping means : 3D printing

- Laboratory