Manual or Robotized.

Laboratory Validation

What is the purpose of laboratory validation ?

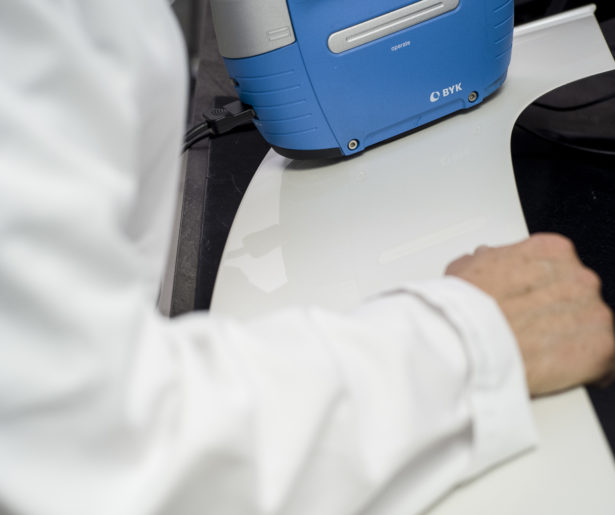

Our client entrust us by providing color samples plates and we will ensure on a daily basis the quality of parts we paint for them

Our manufacturing sites are all equipped with laboratory capability. Multiple control or analysis equipments support daily operations. They can be used for certification of our manufacturing batch or for regular product audits needed in our constant improvement approach.

A good illustrative example of customer trust and confidence level is on display with our historical customer RENAULT who have officialy registered our laboratory in self-agreement. Equally the customer TOYOTA delegates us the responsability of adhesion and humidity tests.

OUR EXPERTISE